The Phlox

The story of the Phlox, why it’s like a boiler explosion, and how plants turn mechanical disasters into survival advantages.

Phlox stolonifera, April 11

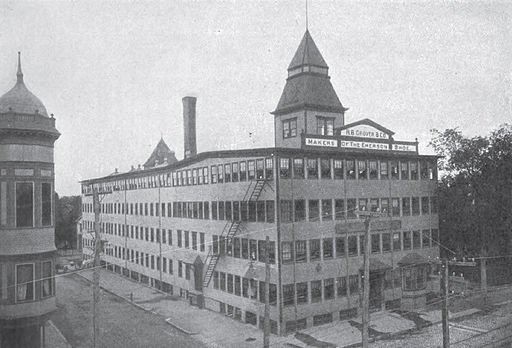

At the turn of the 19th century, on the corner of Calmar and Main streets in Brockton, Massachusetts, stood a large E shaped wooden factory. This was the home of the eponymous R. B. Grover Shoe company, makers of the esteemed Emerson Shoe, with “Soles, Uppers, Linings and Trimmings just as good as money will buy.” The shoes went for the manageable sums of $3.50 and $5.00 and sold well enough to necessitate the addition of a fourth floor to their city block-wide accommodations. With the introduction of extra space came a demand for a new and larger boiler, replacing the 1891 original, which was kept on hand for auxiliary purposes should the need arise.

In late March, 1905, when the updated system required flushing as a matter of routine maintenance, the retired boiler was enlisted for temporary service. At 7:45 a.m., March 20th, the plant manager telephoned David Rockwell, Grover’s Chief Engineer, to ask about some strange noises coming from the radiators along the north wall. A few minutes later, an almighty explosion propelled the boiler up three floors, across the street, and lodged it into the home of one Miss Mary Pratt, who had fortuitously vacated the house moments before.

View of R.B. Grover & Co. Factory, corner of Main and Calmar Streets, Brockton, Massachusetts, before the 1905 explosion.

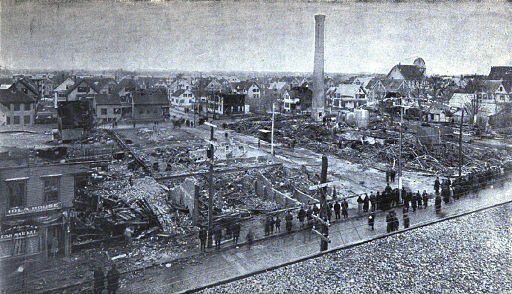

After.

The flying barrel toppled an elevated water tower along its path and its full tank smashed through the roof, causing that end of the building to immediately collapse, with the floors pancaking and the walls falling in on top. Burning coals thrown from the boiler's fire pit landed throughout the debris, starting fires that were fed by broken gas lines. The factory's more than 300 windows, now blown out, created a chimney effect in the parts of the factory still standing, resulting in a fire hot enough to melt iron pipes and radiators. The wooden floors, treated nightly with highly flammable linseed oil to keep the dust down, burned quickly. High winds helped spread the fire to nearby storage sheds and neighboring buildings including a hardware store and a rooming house. “In an hour the four story factory was a blazing ruin. The adjoining business block building and seven houses were destroyed” The Paducah Sun despondently disclosed in the afternoon edition later that day. Miss Mary Pratt survived, as did 250 of the 300 Shoe Factory employees. At least fifty others did not.

The boiler, in Miss Pratt’s living room.

Boiler explosions generally happen for one of two reasons. The first is a fuel/air explosion in the furnace, which would more properly be termed a firebox explosion. The second is a weakness in the tank that causes the barrel to burst along the seam.

In solid mechanics, these weaknesses are referred to as stress concentrations (or stress risers). While stress is generally distributed evenly across solid objects, irregularities such as holes, grooves, joints and notches allow force to converge over a small area, leading often to propagation and failure. This happens at cracks along cast iron bridges, for example, such as the infamous Dee Bridge or Truesdell Bridge. Or can happen, perhaps less spectacularly, whilst stuffing one’s proportions into an old pair of trousers. When blowout occurs along a seem, it is called dehiscence, from the Latin de- ‘away’ and hiscere ‘begin to gape’.

Botanical dehiscence. No ingestion or defecation required.

In the world of structural engineering, dehiscence is consistently a very bad thing, as with bridges and boilers. Plants, however, have learned to leverage stress concentration in their favor. By incorporating weaknesses into their fruits, seed dispersal becomes less reliant on animal hosts. As internal pressures swell with growth, the pod will fail along these risers, allowing the seed to make a timely get away. These intentional flaws can be transverse, valvular, poricidal, or, as in the case of the genus Phlox, longitudinal.

Phlox paniculata

Phlox, a bit ironically from a Greek word meaning flame, is a genus of 68 species of perennial and annual plants in the family Polemoniaceae. They are found mostly in North America (one in Siberia) in diverse habitats from alpine tundra to open woodland and prairie. Some flower in spring, others in summer and fall. The Wild Blue Phlox was one of the first native wildflowers to be collected by European explorers and exported to Europe.

The fruit of the Phlox is a longitudinally dehiscent capsule with three or more valves that split open upon seed maturity. In most cases the seed will simply plop to the ground unceremoniously, but in a few exceptional species, such as Phlox pilosa, the products are spewed forth with eruptive vigor. This explosive dehiscence, or ballochory, ejects the seed (or seeds) from the pod, like water and steam from a lap jointed boiler. A notable example outside this Family is the the Dynamite Tree (aka Hura crepitans), which can blast seeds a ballistically inspiring 300 feet. Anyone standing near it will hear the characteristic booms with each ferocious disruption.

The Dynamite Tree seed pod, flexing its impressive stress risers.

After the 1905 Grover Shoe Factory disaster, an inquest into causation identified a crack in one of the boiler’s riveted, lap jointed seams. This particular kind of joinery allowed corrosion and embrittlement from acidic water and hundreds of cycles of operation to slowly form areas of fragility along the coupling. Met with rising internal pressures, the corrosive fissures gave way, resulting in sudden and catastrophic failure of the iron barrel, blasting it across the street and initiating a cascade of tragedy. At the time of inspection, thousands of lap jointed boilers were still in use in the United States. The Grover event brought new attention to industrial safety and led to stringent safety laws and a national code governing the safe operation of steam boilers.

Phlox stolonifera

Phlox paniculata

Knowledge Sources

https://en.wikipedia.org/wiki/Phlox

http://www.missouribotanicalgarden.org/PlantFinder/PlantFinderDetails.aspx?kempercode=l610

https://indiananativeplants.org/wp-content/uploads/GM_phlox.pdf

http://heritagegarden.uic.edu/garden-phlox-phlox-paniculata

https://en.wikipedia.org/wiki/Dehiscence_(botany)

http://coastalplainplants.org/wiki/index.php/Phlox_pilosa

Kirkman, L. Katherine. Unpublished database of seed dispersal mode of plants found in Coastal Plain longleaf pine-grasslands of the Jones Ecological Research Center, Georgia.

Klaus Kubitzki (2004). Flowering plants, Dicotyledons: Celastrales, Oxalidales, Rosales, Cornales, Ericales. Springer. p. 311. ISBN 9783540065128.

https://web.njit.edu/~sengupta/met%20301/theory%20of%20failure.pdf

https://en.wikipedia.org/wiki/Structural_integrity_and_failure

https://en.wikipedia.org/wiki/Boiler_explosion

http://www.nationalboard.org/sitedocuments/bulletins/fa05.pdf

https://en.wikipedia.org/wiki/Grover_Shoe_Factory_disaster#cite_note-natboard-3

https://en.wikipedia.org/wiki/Stress_concentration

https://gobotany.nativeplanttrust.org/species/phlox/paniculata/

Image Sources

https://commons.wikimedia.org/wiki/File:Grover_Shoe_site_after.jpg

https://commons.wikimedia.org/wiki/File:Grover_Shoe_Factory_before.jpg

https://commons.wikimedia.org/wiki/File:Grover_shoe_disaster_boiler.jpg

https://commons.wikimedia.org/wiki/File:Akelei,_zaadboxen._28-08-2021._(d.j.b)_01.jpg

https://commons.wikimedia.org/wiki/File:Hura_crepitans_5Dsr_6722.jpg